Blog Layout

What is Core Technology?

November 22, 2020

Core Technology – Building Blocks For It All

A lot of terms get thrown around in engineering circles, often to a glazed look from some people in the boardroom. One of them is core technology, which most people tend to assume is the actual “thing” or component assembly that makes up a final product. While that is a loose definition, for the purpose of engaging your electronic component design team on a new project, let’s review a bit to make your conversation more productive, because their understanding of a core technology is probably different.

There is a difference in core technology when you are talking about overall tech and engineering. Those cores are biological, optics, fluid, electrical, electronics, material, structural, thermal, and mechanical. Every system, component, or product is made up of one or more of those core technologies. Once you have something that is made up of parts or systems or proprietary intelligence, then you move into the other definition of core technology, that involving ownership or licensing. That technology is the actual “thing” that is owned or licensed by the License holder, and it may be combined with specific technology that is offered for sale or internal use – a component or product. Much of the later form of core technology falls under the auspice of intellectual property, the holding of which often has intrinsic value and market share due to the particular benefits or industry control that technology is marketed to, or affects. Oftentimes those kinds of core technology are the bridges or leapfrogs that create a vehicle or way to improve performance, user interaction/use, or productivity of a particular product. Many companies, particular in communications, data, medical, and other fields have held a lion’s share of a core technology that made millions or put competitors in the dust.

Why Is a Solid Understanding of Core Technology Crucial in Component Design?

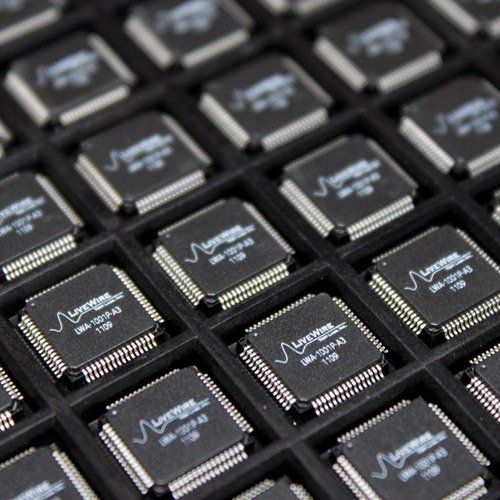

Besides the solid knowledge of the math and physics necessary to calculate and construct functional, efficient component designs, it is critical to your bottom line that any design firm you work with has an understanding of the bigger picture. Success in the market place often hinges on innovation, creative application and design, forward looking adaptation and functionality, and how that all works with manufacturing capability and market conditions. Knowing what and how else other engineering design considerations may affect the potential function and usability of a component, ranging from ambient temperature function ranges to pressure durability, all affect the initial design, cost of production, and fail rate of components. ASIC design engineers need to know not only how to create and prototype a part that does what you want it to, but that it will hold up to manufacturing, shipping, and use, most often over time. They also need to have a solid grasp of the financial considerations, acceptable +/- tolerances, fail rates, and averages such as longevity, run temperature, and a wide range of other factors from other core technology areas that affect their electrical considerations.

Core Technology Has to Effectively Cross Borders as a Universal Language

Thankfully, most reputable component design firms and fabless manufacturing companies speak the same language – that of math and physics. They know that components have to be utilitarian according to a set of facts, theorems and functions. If you need a design done in Dubai with components manufactured in China and assembled in Canada, all those involved have to know, and agree, on just what the component does, how it lends itself to the end product, what is the layout engineered for it all to fit together, and the standards it is tested against. Water flows, heat rises, and current arcs no matter geography or borders. It is a lot easier, though, when you have a design firm with a global perspective and solid contacts and working relationship with the top companies in the world. This helps eliminate questions, errors, and controls costs. One firm that fits all those needs is US-ASIC. They have offices globally and they think globally. They also have some of the strongest relationships with the top fabless component manufacturing firms in the world. Guess work might be helpful in brainstorming sessions about how to create something that has not been done before, but has no place in a quality final electronic component that has to be relied on, every time. Hire a top design firm like US-ASIC and take the guesswork out of your component needs.

A Solid Understanding of Core Technology Goes Hand in Hand With Company Stability

Knowing your stuff means knowing your stuff – all parts of it. A good design firm that only deals with component design might well get you where you want to go and create the part you need. A great design firm knows why you need it, how it will work, what it will cost, and what it needs to do best for your end consumer or use. Those firms also tend to be the ones that have been around a long time, have excellently credentialed staff with expertise not only in their specialty, but an understanding of how what they are doing for your company affects other things, or is affected by other parts or issues within a design. They stand behind their work and work until it is right. And, they will be there six months later when technological advances demand an update, without a full fresh start to achieve whatever modifications your task at hand might require.

Why Are Electronic Components So Critical to Other Core Technology Projects?

The simple answer is often the need for power. Electronics and electrical technology utilize amounts, however small, of electricity to measure, gate, weigh, enact, trigger, control, data mine, store, receive, retrieve, process, communicate, and detect in a vast majority of things that are made. That ability to use those bits of energy in a form that maximizes the potential to get work done is often the starting point or pivot of a design project. It is therefore imperative that an ASIC or analog design engineer is knowledgeable about how and what the component is to do, but also what else it has to work with, to design the best possible component for the task. The ability to communicate, ask questions, and function as a member of your team helps control design and run costs, as well as saves frustration and stress for your engineering and manufacturing personnel. A fluid design that is thought out from start to finish provides a top quality product at a good price. It also assures a consistent manufacturing base, making it much easier to outsource production to a top line fabless component manufacturing firm. They know, and you as well, that what is being assembled will work exactly as you need it to, without having to go back to the drawing board.

February 13, 2021

Basics In Electrical Components Start As Simply As What Is Voltage If you are an electrical engineer, you already know that. Before you scoff, however, stop to thing that your purchasing manager or CFO might not. One of the most common things we hear when we go into a company to consult to solve challenges or design specialized components is “they don’t understand.” It is not just on the more refined technical engineering side, either. Purchasing agents and buyers find it frustrating to try and learn the basics of information they need to make accurate choices in assigning vendors for bid, or what to ask for on follow-up for specs. It could be as complex as gate arrays, or as simple as what is voltage and why is it important to know the difference between it and current. When You Have Need To Provide A Definition Of Voltage, You Need To Discuss Pressure Electricity is one of those subjects that confounds and confuses most people, partly because of the math, and more because it is simply unseen save the results or lack thereof. When you are in need of specialized components for a development project, it can sometimes be very helpful to think in terms of the expertise the person handling procurement for your project may or may not have. Taking a few minutes to share some basic terminology can go a long way to alleviating errors in specification approvals or to minimize ordering issues. It could even lead to cost saving measures when a component capable of multiple tasks, such as an ASIC, is available. You and your procurement team need to have a conversation. Voltage truly is a pressure or force, one that moves charged electrons (commonly called current) through a given conductive element, item, or space (loop). That kinetic movement pushed through a loop is what allows work happen, i.e., the current creates a power source from the potential energy to make things run, such as a starter motor. In a power source that has poles or ends, such as a battery, that potential difference flows from the positive electron end to the negative and out, a process known as the difference between two points. That difference is creating the energy and a current will flow. That energy can be used for a task, such as lighting a light bulb. Excess energy then flows back to the power source. Some Historical Perspective Helps Define Voltage And Make Sense Of Terms To be more accurate, voltage is a measure of force, rather than the force itself. Voltage equals pressure, and is measured in volts (V). It was named after the Italian physicist that identified and quantified voltage and its “form”, Alessandro Volta. His work in the late 1700’s to early 1800’s led to his building a voltaic pile, the predecessor to our modern batteries. In the early days of working with electricity and its various elements, voltage was referred to as electromotive force (emf). That is why to this day various formulas about electrical current, voltage, and their interrelationship will use “E” to represent voltage. One of the most commonly known of these formulas is “Ohm’s Law” - E = I x R (voltage = current times resistance). It is also known as volts = amps (x) ohms. Voltage And Current Are Not The Same Thing Often when you overhear laymen speaking about electricity and values, they refer to current vs voltage as if they are opposing forces, or the reverse, that they are one in the same thing. They are neither. Voltage is the charge difference between two points while current is the rate at which the charge is flowing. That voltage difference is the change in the actual charge as it travels over one point on the way to the next. The other is by how much. Another way to look at it is voltage, or electromotive effect, is the cause, and current is the effect, what actually “happens”. You Are Thinking "I Know All About Voltage Definition. Why Is It Important?" It is most important to you as an engineer to know how much current is required to get something to run, or how resistance is going to play into the efficiency of something you design. They are probably every day elementary calculations to you. But what if the person you are speaking with about an integral part for a new telecommunications device does not understand that every detail on your specifications needs to be followed to the letter, and terms are not easily interchangeable? I can hear you shaking your heads no, but problems like this come up every day in purchasing departments and between those who take care of paper and those who design and discover. What if your person with the big idea knows what it needs to do, but not how it necessarily needs to work? Obviously for a hi-tech firm this is not an expected scenario, but trust me to say that it happens more often than you would like to know in regular day-to-day application where components and parts need to be custom designed to regulate a function, control a feature, or improve a product. And, often the people who need it fixed do not know the “real” terms for things as simple as amps, ohms, voltage, and resistance when electrical circuits are involved. The Correct Electrical Charge And Choice Comes Down To Money The reasons you should care boil down to money. Components with ordering errors, those with problems in interpretation of specifications end up costing manufacturing millions of dollars a year in shrink due to errors. That does not even count the time spent designing, waiting to manufacture at a fabless facility, shipping, installation/build, and then learning the part is not adequate to carry the current needed to operate the piece of equipment, or worse, causes a safety issue. Trust me when I tell you that even if the plant is self-contained, often departments do not communicate well with each other. The potential for greater misunderstanding is greater when the plants are scattered over the globe, or the person responsible does not understand the international system of units. A little education can go a long way to a final product in on schedule and within budget that does exactly what you need it to do, perform, or manage in a final product. Your Company's Electrical Potential Starts With A Team You Can Talk To Commonly used terms in the field of electrical component design are not common to many people that have to interact with those of us “in the know.” When you are having parts designed for a final product, you need to have a design team and engineering staff that can talk to everyone on your team with clear, concise, understandable terminology, whether it is your chief engineer or the QC person who has to check the inbound shipment. They all need to know what it should look like, how it should be labeled, and how to tell things apart. Good quality control starts with things as simple as knowing what voltage is and isn’t, so they know that a 1.5 volt battery versus a 15 volt one is totally different voltage but current is the same. It starts with hiring a solid design team that can work with your staff at all levels, eliminating errors, re-runs, spec mistakes, and budget overruns. US-ASIC is one of those companies with a great deal of experience, superb client interaction, and they have some of the best agreements for fabless semi-conductor and component manufacturing in the world. We know how to communicate with everyone on your staff. Check them out and you won’t find yourself in the predicament of explaining to your staff what voltage is after it’s too late.

By Marilyn

•

November 4, 2020

Before You Ask How to Program a FPGA, You Might Want to Know What One Does in Simple English You know the question is coming when it starts with “well what does it do?” when you are having a discussion with a party not privy to the inside, electro-techno world of semiconductor products and what they are, do, and can do. An ASIC design engineer certainly can give you a thorough response that rattles off all the parts and pieces and circuits and interrelated items that go into some digital design. Sometimes, though, you need to be able to explain in more street savvy terminology just what you are trying to achieve, and why with what parts, to someone who truly is trying to wrap their understanding around your question or comment on your current electronic component need. A truly customer-forward semiconductor design company should have staff that can talk to all parts of your organization, in language they can capture and act upon - not just the engineer or design folks. So Just What Is an FPGA? It’s Not Golf for Girls. An FPGA , or Field Programmable Gate Array, is a specialized programmable silicon chip (semiconductor component or device) built around a grouping of logic blocks. This basic unit can be programmed or reconfigured by an ASCI engineer to allow access to and/or through a logic gate. The logic gate often is a group of input/output blocks (IOBs) that act as a gateway system or channel for information or energy flow between the program in question and the rest of the system. The programming or configuration allows an application or function the engineer or designer wants to have happen or be allowed to occur. A hyper simplified way of looking at it is doors with treats behind them. Your dog (the signal) learns (is programmed through being trained) to step on (open) a gate (the FPGA) to achieve a goal or action (open the door, get a treat). FPGAs are semiconductors that use these groups of CLBs or configurable logic blocks to house an application or function needing to be achieved or activated. These requirements often are steps in a build to achieve a component integral to some manufacturing process. Why Would I Want to Program an FPGA? FPGAs are particularly helpful to a semiconductor companies’ integrated circuit design engineer working on a prototype for a future refined, specific application circuit. Since an FPGA can be reprogrammed repeatedly until the ASIC or application-specific integrated circuit or processor is in final form, debugged, and working exactly as desired when integrated into an overall design, it is extremely useful during new or improved product development. The engineer can put in a register, lookup table or other block logic function, making the abilities of the FPGA to do a variety of tasks through one component a big plus. FPGA’s can be a very cost effective, time saving component that make tweaking a semiconductor, integrated circuit, or other part faster, easier, with less challenges to use in the most often severely limited space and tight tolerance world of electronic components. Since FPGAs are parallel (the signal flows two or more ways) instead of only in a straight line like a semiconductor, they are extremely useful as “test building blocks” during the semiconductor design phase. Their ability to “multi-task” makes them a workhorse of semiconductor chip design. Programming an FPGA is Pretty Simple, Right? Not Really. And They Are Not Really Programmed. What I mean by FPGA’s are not really “programmed” is they actually experience more like code being written. FPGAs work in what are called hardware description languages or HDLs. Many of the languages used are upwards of 40 years old. Those languages are what create circuits when you write the text, which is turned into a binary file (remember the old math class problems figuring out what 10100101 was? 165 for you number heads out there.) The files can become really complex and complicated to write out in a standard schematic form or tree, so what the programmer does is describe what they want the circuit (FPGA) to do and tell it what tools or parts to use to achieve it. The binary code (text) gets compiled, a sometimes very long process. It is not unusual for an FPGA “programming” to take four to twelve or more hours and then has to be recompiled every time there is a correction, modification, or tweak to the text (i.e. because something is still not working exactly as desired in the component). That is why it is important to have an ASCI chip design team working on your project that has a very good working understanding of what you need the overall component or semiconductor to achieve or do once perfected. The better input, the better output, so to speak, like all computer work. This is Why Being Able to Explain What You Need It To Do – And Understanding the Answer – is So Important to Your Bottom Line There are a lot of semiconductor and ASIC design firms that will tell you they can design “just what you need”. It sounds great until you start seeing overrides, requests for schedule extensions, or other issues. Those all equal money. You need to work with a company to do your manufacturing plant FPGA and other semiconductor chip design that not only “gets” what you need done, but has the expertise to do it with minimal changes to the design to get it done right and within budget. Their staff needs to be able to listen and communicate, whether it is with your Director of Engineering or your purchasing agent, with patience and verbiage that accurately tells the story. They need to be able to do it all on time, in budget, and with a quality, space and cost efficient design that can easily be sent to a fabless semiconductor company for manufacture as easily as a custom build component shop. Their reputation and relationships within the industry should be solid and show the results of their work through reliable component development and happy, repeat clients. Bottom line, they should honor your budget, your timeline, and save you stress. One of the best ASIC semiconductor design companies around that meets and beats all those criteria is US-ASIC . Years of experience and the long-term relationships to prove it, US-ASIC continues to be voted year after year as one of the top, best, easiest to deal with, fairest priced component design firms in the world. They can handle your ASIC, FPGA, analog, and a wide array of other needs and formats. Give them a call and tell them you need a component built that sure would be faster to tweak and test with one of those gateway I/O block things. They will know exactly what you need done and have the knowledge to get it designed fast and right.

August 17, 2020

What You Want From Semiconductor Companies Working For Your Company Semiconductor products can be some of the most important but daunting components of any manufacturing process. After assessing what you need a part to do, it then becomes a question of can it be made, do we have to make it, or can it be manufactured for us at a reasonable cost? Components need to be of high quality with consistent performance without breaking your budget. It is rarely cost effective to try and manufacture your own electrical components, as semiconductor chip design is a specialized field and manufacturing taking expensive equipment, costly and often difficult to source raw materials, and a tightly controlled plant environment to have it all come out correct and functional. Finding a chipset design engineering company that listens and understands your needs and has access to top line manufacturing plants around the world can save time, money, and frustration. This becomes especially true when you need the capabilities of a fabless semiconductor supplier specializing in analog design and manufacturing. At US-ASIC , we know that chipset design can be daunting. We specialize in taking your need, thoroughly understanding what your end result needs to be, and how the semiconductor component needs to function. We work closely with your team to listen, learn, and either create a design or take what your team has assembled to evaluate what you need to meet your goal and source the part. We then engage the best fabless semiconductor companies around the world from our large network that can most effectively, on the best delivery schedule and at the best price, manufacture your chipset. We have many years of experience designing and procuring for major manufacturers and end-users in a wide variety of industries from telecommunications and medical to technical manufacturing, and we would like to be your go-to source for semiconductor engineering and supply. We take the guesswork, frustration, and negotiation time out of the equation, making your process faster, simpler, more consistent, and less stressful. Contact us to experience the difference in utilizing an engineering design staff that takes the time to work with you for the best possible end result. Communication With Your ASIC Engineer Should Not Be Painful If you are like most manufacturing plants, you have people who do specialized jobs, and it is important that all the various “parts” communicate not just well, but as seamlessly as possible in order to achieve your goal – a cost effective, well manufactured product that generates sales. Or perhaps you need parts to help complete particular tasks in your own plant, but explaining what needs to happen to meet the desired outcome can be a challenge. Finding semiconductor design companies that speak your language can be a challenge. Most numbers people don’t know quite how to explain what they need in a chipset design and the task it needs to complete to the average integrated circuit designer engineer. Our design team does, knows what to ask, how to analyze and assess, and can create or recommend a solution. At US-ASIC, we believe in helping make your project stay both on time and in budget. We also believe strongly in solid, efficient, thorough communication with all levels of the procurement process, in language that can be understood. US-ASIC can be a major asset to help you achieve chipset design that is effective, efficient, and on price point. Our world wide base not only means we literally speak your language, we also excel in taking your ideas, rough drawings, or engineering specs and matching them with an ASIC design engineer “liaison” to not only handle the technical aspects, but who can explain in detail what your needed semiconductor products have to do, how they should function, and what task they need to complete. We speak business, manufacturing, and engineering equally well, and can translate your needs to high quality engineering specifications about what you need made, as well as source fabless semiconductor companies to do it swiftly and at a price that keeps manufacturing expenses under control. Chip Design Done Right – US-ASIC It is often a challenge to find exactly the right semiconductor component you need for a particular application. Too often chipsets are designed to meet a wide range of generic uses, which means they often are larger or not specific enough for the best application and operation of your particular instrument, device, or machine. At US-ASIC our knowledgeable team of semiconductor engineers and designers work with you to provide a design that specifically addresses what you need a semiconductor or other component to do within the configuration and space you need it to work. We know that cost is tantamount for any manufacturing need, whether a highly specialized part for industry specific manufacturing, or parts that go into mass market electronic devices that need to be reliable and margin friendly. Call us at the nearest office and set up a time for us to review your plans and drawings along with a discussion. As a world leader in the fabless semiconductor supply chain, we have already done the legwork of qualifying manufacturing facilities that can meet your need at the best price with reliable, high quality electronic components. At US-ASIC we believe it is important to communicate with our clients to establish exactly what they need. Our multi-cultural approach assures you that we can listen to what you need on your terms, on your budget, and on your schedule. We have many years of expertise, a highly trained, qualified design and engineering team, and we can be as straightforward or as innovative as you need on a semiconductor design. Our reputation and longevity speak to our strong industry agreements and sourcing. Avoid tooling up, or spending precious production time hunting parts. US-ASIC is a world leader in semiconductor design and fabless semiconductor supply. Contact us and let’s get started on the component solution you need to find. Interested in our solutions? Check some of them out here: Digital Signal Processing Foundry Access Wire Telecommunication

July 29, 2020

It used to be when someone got an idea to make something, they often had to dream it up, do the drawings, figure out the equipment necessary to build it, and then arrange financing to obtain a building and equipment. Sometimes there was no equipment made to build what they had invented, or needed to build better and cheaper than was currently available on the market. That meant retrofitting or special tooling of equipment – both expensive propositions. Once all that was done finding qualified staff, raw materials that would meet specifications, and working out the bugs on the production line loomed ahead. That all had to happen before the first product rolled off the end of the line and into a box or package so the new sales staff could sell it with help of your marketing department.

July 29, 2020

Semiconductors are some of the most simple electronic components, but do some of the most complex tasks imaginable. They are manufactured from silicon, one of the most abundant elements in the earth’s crust. Molten silicon allows a chemical bond to grow a bell shaped parcel called a boule or ingot around a seed particle, creating uniformity, consistency, and traits that allow the silicon to be sliced microscopically thin or formed into tiny bodies that make up electrical components. Semiconductors are created when various elements, such as phosphorus containing soil, are added to the silicon, giving the final product different characteristics.

Northern Europe/Scandinavia

Contact: Lars NilssonTel: +468 6695650E-mail: Lars.nilsson@us-asic.com Mobile: +46 70 5958081

Asia

Contact: Steve ChoiTel: 82-2-2057-2877

(#1000)E-mail: asifs@norcalts.com

Privacy Policy | Terms & Conditions | Copyright 2022 U.S. ASIC | Website & SEO by Iron Oak Marketing